Kegland

Rapt Fermentation Chamber - PREORDER

Rapt Fermentation Chamber - PREORDER

Stock would be available Early March

Many home made products can greatly be improved with perfect temperature control. The RAPT Temperature Controlled Fermentation Chamber gives you an electrically efficient means of setting, monitoring and controlling temperature which is perfect for Beer Making, Wine Making, Salami Making, leavening bread, fermenting yogurt, kombucha, germinating seeds, growing sprouts, kimchi, sauerkraut, olives, cheese, making spirit washes. Accurate temp control is the key to getting reliable and repeatable results.

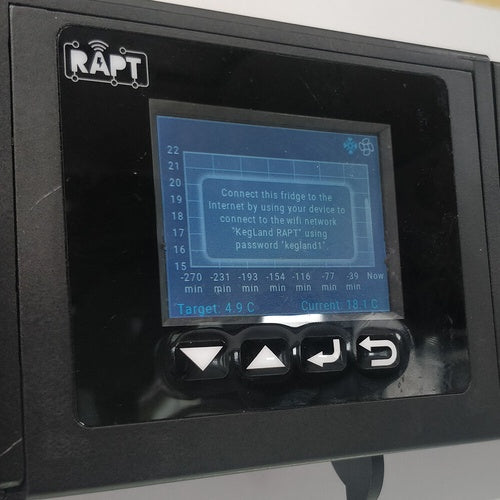

The control panel comes complete with an integrated color TFT screen, the integrated secondary regulator that can be used to regulate gas into the fridge with our Inline Regulator with an integrated gauge or alternatively this can be switched over to the Gauge integrated BlowTie unit to regulate residual pressure in your fermenter. The 4 button color display conveniently shows a log of historic temperature graphs, allows you to start, set/stop temperature profiles and gives you access to other critical information for that particular fermentation.

For more accurate readings of the core temperature of your fermenter. We highly recommend using a thermowell like our 60cm Duotight thermowell with the 6.5 ft. probe extension for the RAPT Fermentation Chamber.

Perfect as a Kegerator too!

This multipurpose fridge can also be used as a kegerator. In particularly cold climates where the ambient temp is below zero, this fridge can warm your kegs and prevent them from freezing. This fridge also has a higher keg storage capacity than a conventional kegerator that takes up the same footprint. This unit can hold 4 x 5-gallon kegs on the floor and has enough headroom that you can also fit another layer of 2.5-gallon half size kegs above this. To fit beer taps you can drill your own holes through the door.

What is RAPT?

RAPT is a dedicated Internet of Things (IOT) Hub for fermentation logging and control. It's a free service whereby any RAPT enabled product can both log and store data to the hub where you can conveniently access this data. The RAPT hub can also allow you to control your devices remotely giving you absolute control of the device irrespective of where you are. The RAPT portal enables you to make complex temperature profiles that involve different temperature settings over time meaning you can start/run a temp profile giving you a set and forget experience. The RAPT portal also controls the alert/notification process for you so you can receive email notifications in the off chance that something doesn't go to plan.

Specifications:

- Integrated Heating: 50W Heating Power

- Cooling Capacity: 300W Cooling Power

- Max Power Consumption: 225W

- Refrigerant: r600a

- Connectivity: WiFi (802.11) and Bluetooth

- Temperature Accuracy: +/- 0.1°C

- Temp Resolution: 0.1°C

- Integrated Screen: 2.8" (diagonal) 320 x 240 Color LCD TFT Active Matrix

- 110V

- ETL Certified

External Dimensions:

- Width: 21.25"

- Depth: 24"

- Height: 69.3"

Internal Dimensions:

- Width: 17.3"

- Depth: 19.6"

- Height: 51.2"

Why buy a fridge over a glycol chiller?

Typically in the past, some customers have needed to resort to glycol chillers to chill fermenters but this represents several issues:

- Glycol chillers often require a very cold liquid to enter into a fermenter causing an excessively cold part in the fermenter core.

- Glycol chillers consume significant amounts of power and in most instances more than double what this fridge would consume.

- Glycol chillers often result in spilling sticky glycol especially when hoses are connected and disconnected to the fermenter.

- Glycol chillers generally require penetrations through the walls/lid of the fermenter making the fermenter less sanitary and requiring more cleaning. "who needs that!"

- Often fermenters are not made with sufficient insulation. So when using a glycol chiller much of the chilling is lost which is not only power inefficient but the customer ends up with a large temperature gradient. This temperature gradient can result in convection currents in the fermenter that make it difficult for yeast and other solids to settle out of suspension. So clarification of the beer takes significantly longer.

- Many glycol chillers and fermenter combinations do not have sufficient power or are not well enough insulated to cool to sub-zero temperatures. So crash chilling is not possible. This is a significant compromise to a temperature-controlled solution and also results in less ability to clarify the finished beer.

For these reasons KegLand has developed the world's first dedicated RAPT enabled fermentation chamber that can cool down to -2C and heat up to 50C even in hot and cold weather.

Share

Couldn't load pickup availability